WHO WE ARE

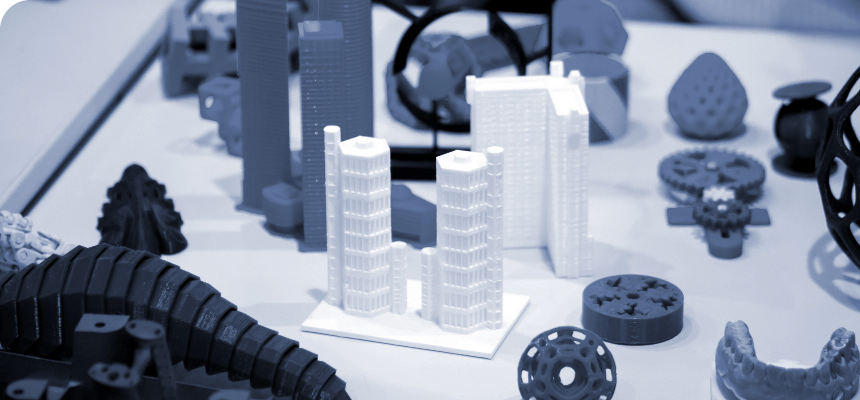

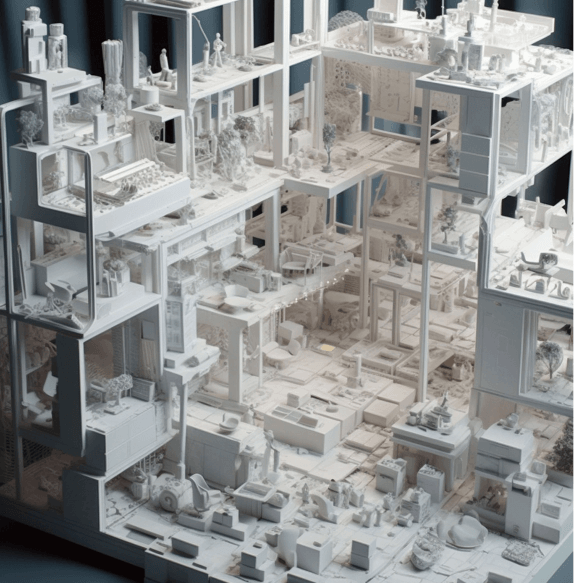

Turning your ideas to reality with our advanced 3D printing technology

OUR VISION

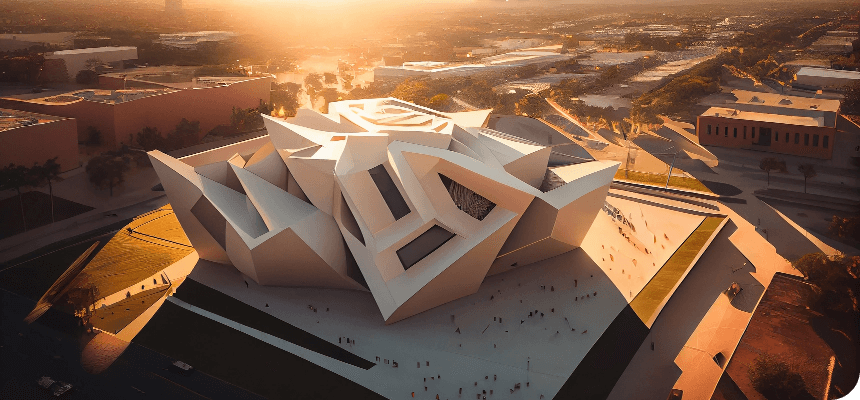

Tvasta shall be a technology platform in the machine, material, and software domains, offering end-to-end application-based solutions across all sectors of the construction industry. Through innovation and advanced 3D printing technology

OUR MISSION

Tvasta, a first principles-based technology builder, will use the power of Automation and Robotics to build 3D Printing Platforms that enable the building of infrastructure and manufactured components faster, cheaper and in a more sustainable manner.

Tvasta will develop category-creating platform technologies that disrupt the Construction Industry by automating 80% of construction while building distributed Infrastructure solutions and mass customization of end components.

Tvasta will develop 3D printing by creating specific technological platforms that can be used for applications across the Manufacturing sector for producing mass customised end components with high precision.

We take pride in delivering high-quality, unique structures that are built to last with cutting-edge technology.

Our 3D Printing Process

STAGE 1

Model Design

STAGE 2

CAD Model To C3D Print Format

STAGE 3

Marketing Concrete Paste

STAGE 4

The Printing Process

STAGE 6

Final Tangible Model

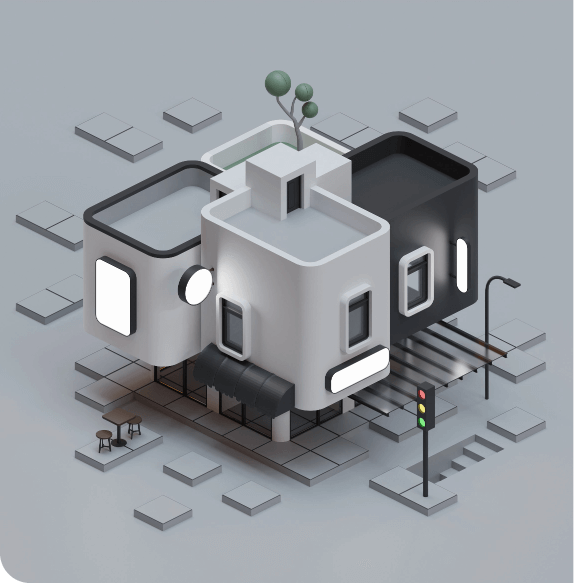

Types of construction 3D printing

Offsite Methodology

Phase 1

- Architectural Design

- Conversion Of 3D Printable Format

- Printing And Execution Strategy

Phase 2

- Printing

- Curing

- Primary Quality Check

Phase 3

- Foundation Work

- Transportation And Unloading Of Printed Modules

- Secondary Quality Check

- Assembly

Phase 4

- Reinforcement

- Grouting

- Finishing

Onsite Methodology

Phase 1

- Architectural Design

- Conversion Of 3D Printable Format

- Printing And Execution Strategy

Phase 2

- Foundation Work

- Printer Deployment At Site

- Printing

- Curing

- Quality Check

Phase 3

- Reinforcement

- Grouting

- Finishing

The Experts Behind the Innovation

CEO

Adithya

Adithya is involved in business development through formulating collaborations with institutes for new product generation and commercialisation of our deep tech products and services.

CTO

Pragadeeswar

Pragadeeswar is responsible for the engineering aspects of 3D printers and the printing process. He also oversees the research and development activities of the company.

COO

Parivarthan

Parivarthan deals with the operations of the company and streamlines design, implement policies to promote company culture and vision and oversee operations to keep businesses on track.

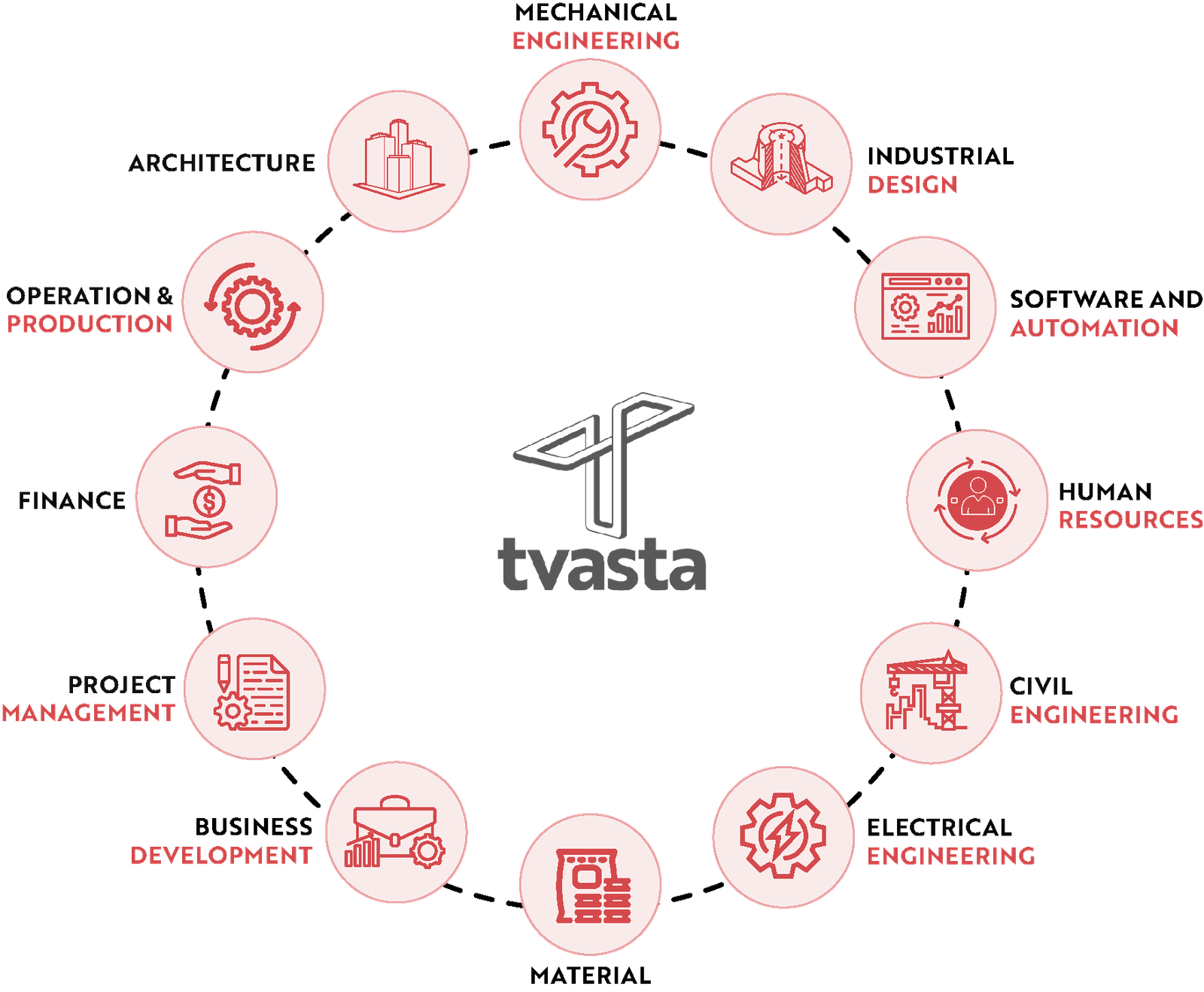

Team Structure